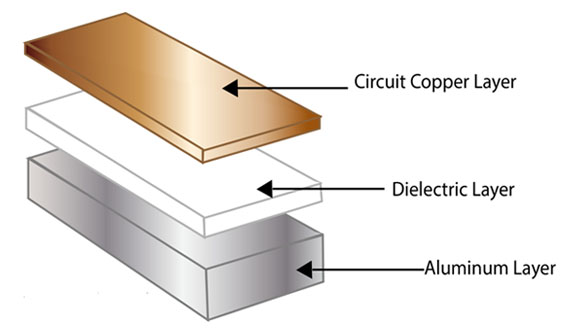

Metal core PCB (also MCPCB) is kind of PCB with metal base material instead of woven glass FR4, FR3 or others. There is single sided, double sided, multilayer and COB. The common used metal core is aluminum, copper and alloy. Aluminum is the most frequently used among them due to its good heat transfer ability, dissipation ability and relatively cheaper cost than copper, although which may has a better performance. Single sided metal core printed circuit board consists of a metal base (aluminum or copper alloy), dielectric layer, and copper conductor layer. The single layer MCPCB can be used with surface mount and chip & wire components. It provides much lower thermal resistance than FR4 PCB. And the metal core provides lower cost and allows much larger areas than ceramic substrates.

Metal Core PCB is used to replace traditional FR4 or CEM3 PCBs because of the ability to efficiently dissipate heat away from the components. This is achieved by using a thermally conductive dielectric layer. The prepreg dielectric provides excellent heat transfer from the foil and components to the base plate, while maintaining excellent electrical isolation. The base aluminum or copper plate gives the single-sided substrate mechanical integrity, and distributes and transfers the heat to a heat sink, mounting surface or directly to the ambient air.

| Base material: | Aluminum, Copper, Iron Alloy |

|---|---|

| Thermal Conductivity (dielectrial layer): | 0.8, 1.5, 2.0, 3.0 w/m.k |

| Board Thickness: | 0.5mm~3.0mm (0.02″~0.12″) |

| Copper thickness: | 0.5oz, 1oz , 2 oz, 3oz , up to 6oz |

| Outline: | Routing, punching, V-Cut |

| Solder mask: | White/Black/ Blue/Green/Red Oil |

| Legend/ Silkscreen Color: | Black/White |

| Surface finishing: | Immersion Gold, HASL, OSP |

| Packing: | Vacuum/Plastic bag |

| MCPCB Type: | Single sided MCPCB, double sided MCPCB, COB MCPCB, multilayer MCPCB |

| Mfg Volumes: | Prototype, Small, Medium |